Sheet & Plate

Sheet & Plate

At Diya Steelloy, we offer high-quality Sheets & Plates designed to meet diverse industrial requirements. Our range includes materials like Alloy Steel SA387 Grade 11, 12, 22 and Corten Steel, known for their exceptional strength, durability, and corrosion resistance. These products are ideal for use in boilers, pressure vessels, heat exchangers, structural components, and outdoor fabrication. With excellent high-temperature performance, weldability, and dimensional accuracy, our sheets and plates ensure reliable performance in demanding environments.

Available Grades of Sheet & Plate

| Material Type | Available Grades |

|---|---|

| Alloy Steel | SA387 Grade 11 / SA387 Grade 12 / SA387 Grade 22 |

| Corten Steel | A242 / A588 / IRSM 41-97 |

Dimensional Table for Sheets & Plates

| Parameter | Range / Specification |

|---|---|

| Thickness | 0.5 mm to 150 mm |

| Width | 600 mm to 3000 mm |

| Length | 1000 mm to 12000 mm (or as per requirement) |

| Available Forms | Sheets, Plates, Coils, Strips |

| Edge Condition | Mill Edge, Sheared Edge |

| Surface Finish | Hot Rolled, Cold Rolled, Pickled, Polished |

| Tolerance | As per ASTM / EN / IS Standards |

Types of Sheets & Plates

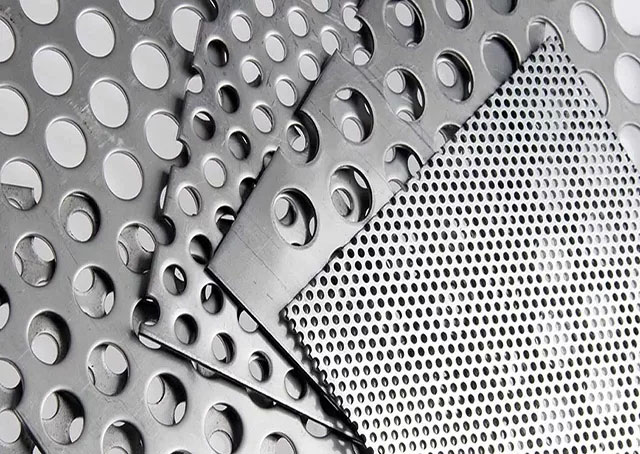

Perforated Sheets

Perforated sheets are metal sheets that have been manually or mechanically stamped or punched to create a pattern of holes, slots, or decorative shapes. These sheets offer excellent ventilation, aesthetic appeal, and functionality across various applications such as architectural design, filtration, acoustic control, and industrial screening. Available in different materials including stainless steel, aluminum, and mild steel, perforated sheets provide a balance between strength, lightness, and open area.

Key Features:-

-

Customizable hole sizes, shapes, and open area percentages.

-

Provides effective airflow, light filtration, and acoustic performance.

-

Manufactured in stainless steel, aluminum, mild steel, and other alloys.

-

Corrosion-resistant and suitable for both indoor and outdoor use.

-

Widely used in architecture, HVAC systems, machinery guards, and filtration units.

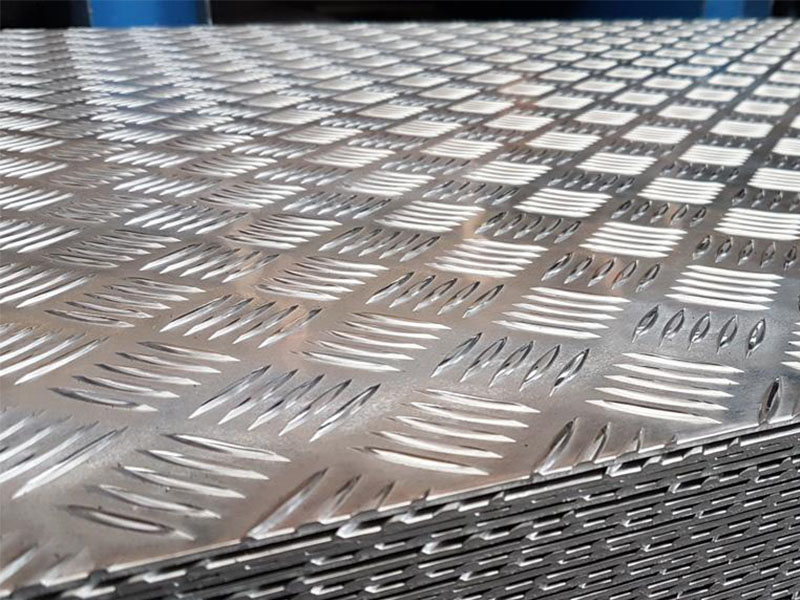

Chequered Plates

Chequered plates, also known as tread plates or diamond plates, are metal sheets with a regular pattern of raised diamonds or lines on one side. These plates are designed to offer enhanced grip and traction, making them ideal for flooring in industrial areas, stair treads, walkways, and transportation vehicles. Known for their durability, anti-slip surface, and impact resistance, chequered plates are commonly manufactured in mild steel, stainless steel, and aluminum, and are suitable for both indoor and outdoor applications.

Key Features:-

-

Anti-slip surface pattern for improved safety in wet or oily environments.

-

High load-bearing capacity and excellent durability under mechanical stress.

-

Available in materials like mild steel, stainless steel, and aluminum.

-

Corrosion-resistant finishes suitable for indoor and outdoor usage.

-

Ideal for industrial floors, ramps, staircases, bus flooring, and truck beds.

Shim Sheets

Shim sheets are precision-thin metal sheets used to fill gaps, adjust clearances, or provide accurate alignment between machine parts. Known for their dimensional accuracy, flatness, and corrosion resistance, shim sheets are essential in industries such as automotive, aerospace, electrical, tooling, and construction. They are available in a variety of materials including stainless steel, brass, copper, aluminum, and carbon steel, and are often used in die setting, machine repair, and structural support applications.

Key Features:-

-

High precision thickness with tight tolerances for accurate spacing and alignment.

-

Available in a wide range of thicknesses from 0.05 mm to 3 mm.

-

Manufactured from materials like stainless steel, brass, copper, and aluminum.

-

Excellent resistance to heat, corrosion, and mechanical wear.

-

Widely used in tool & die setups, machine components, and structural leveling.

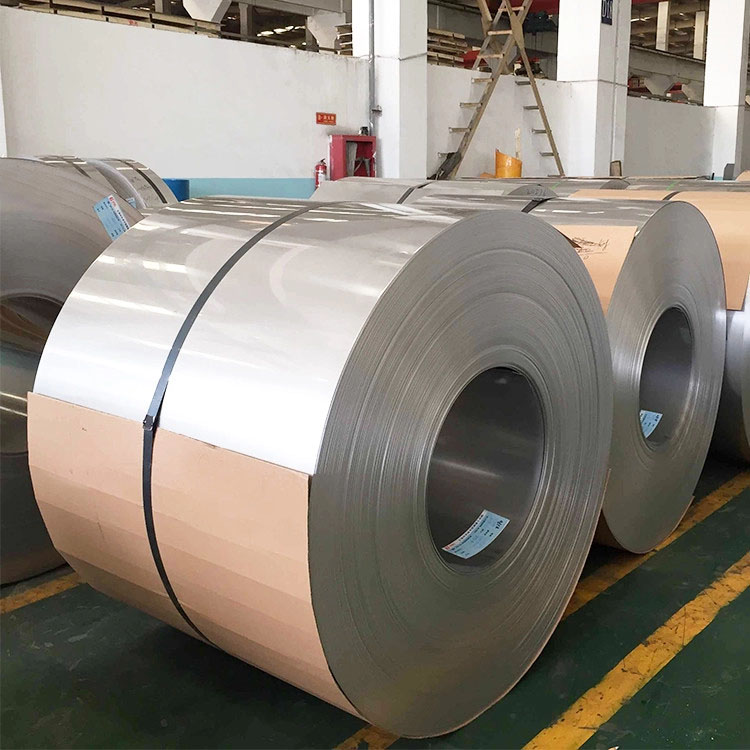

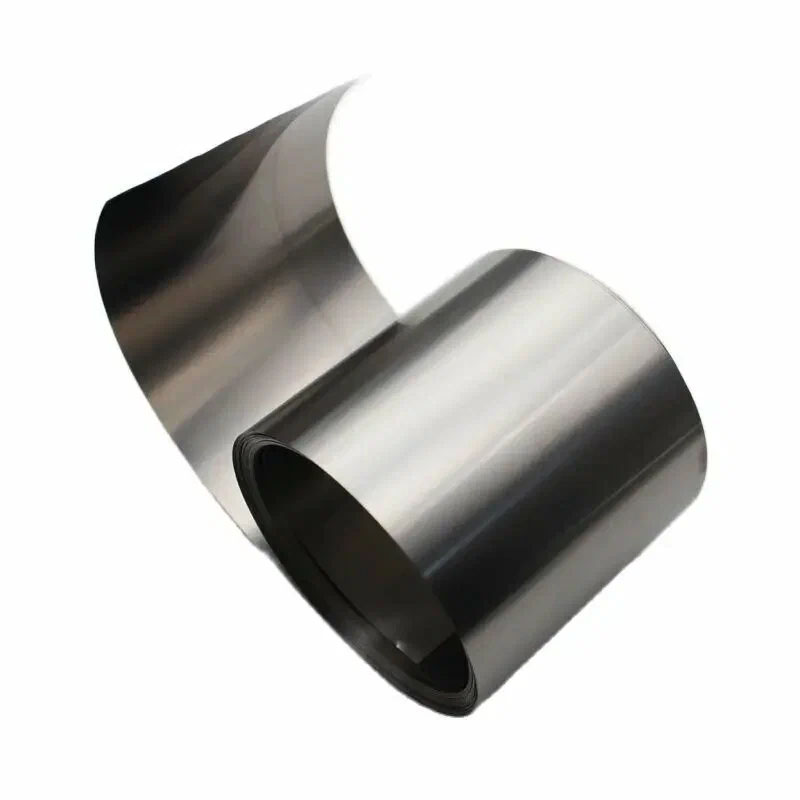

Coils

Coils are continuous lengths of metal sheets wound into rolls, used across various industries for their easy handling, efficient storage, and versatile fabrication capabilities. Available in materials like stainless steel, carbon steel, alloy steel, and aluminum, coils are commonly used in automotive components, appliances, roofing, construction, fabrication, and industrial machinery. Coils are produced through hot rolling or cold rolling processes and can be further processed into sheets, strips, or other custom forms as per requirements.

Key Features:-

-

Available in hot rolled, cold rolled, and galvanized finishes.

-

Suitable for slitting, shearing, and further processing into sheets or strips.

-

Manufactured in stainless steel, carbon steel, alloy steel, and aluminum grades.

-

Excellent strength, dimensional consistency, and surface quality.

-

Used in automotive, construction, HVAC systems, appliance manufacturing, and more.

Strips

Metal strips are thin, narrow sections of metal coil or sheet precisely cut to specific widths for use in a wide range of industrial and manufacturing applications. Strips are known for their flexibility, precision tolerances, and high strength, making them ideal for automotive components, electronics, springs, washers, blades, and sealing systems. They are commonly available in stainless steel, carbon steel, brass, copper, and aluminum, and can be supplied in various surface finishes and tempers based on end-use requirements.

Key Features:-

-

Precision-cut to narrow widths from coils or sheets.

-

Available in annealed, half-hard, and full-hard tempers.

-

Manufactured in stainless steel, carbon steel, copper, brass, and aluminum.

-

Excellent surface quality, thickness uniformity, and dimensional control.

-

Used in precision stamping, electronics, gaskets, shims, and industrial tools.

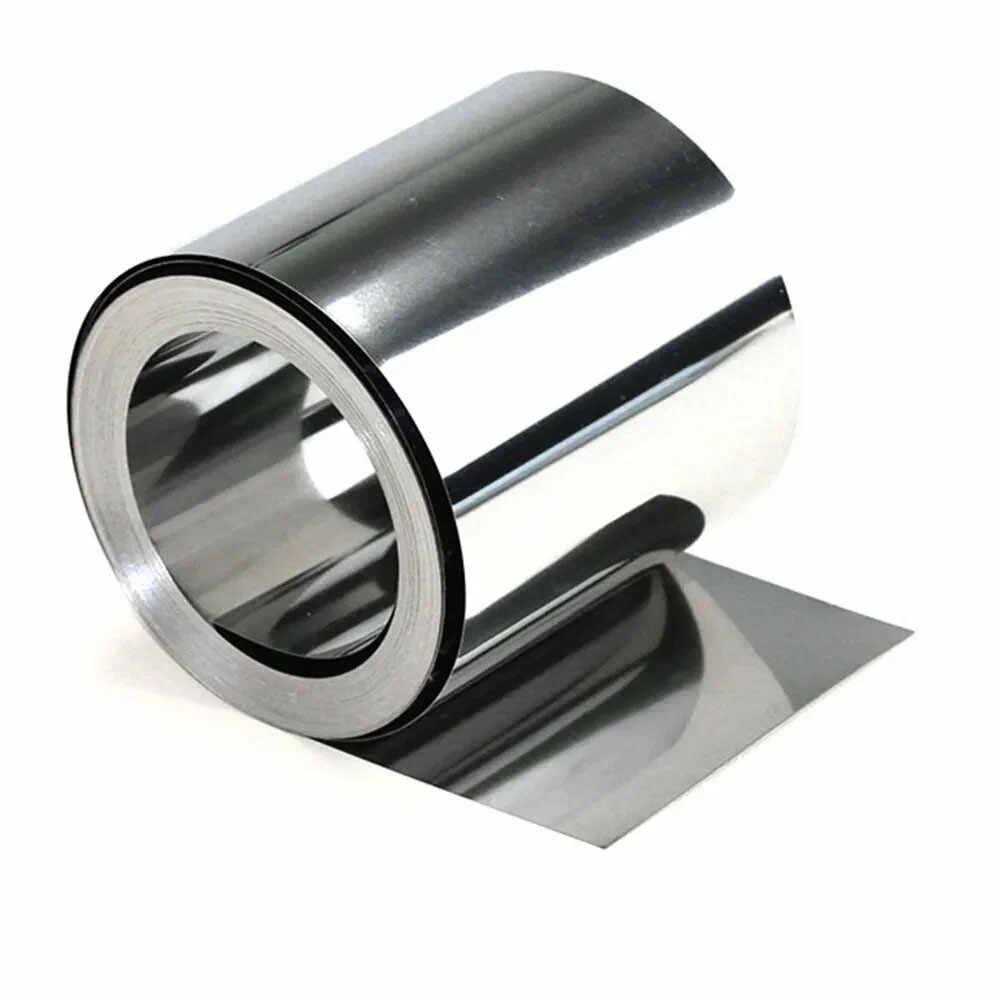

Foils

Metal foils are extremely thin sheets of metal, typically less than 0.2 mm in thickness, used in applications where flexibility, lightweight, and conductivity are essential. These foils are known for their high malleability, thermal and electrical conductivity, and corrosion resistance. They are widely used in electronics, insulation, packaging, EMI shielding, and aerospace applications. Foils are available in materials like aluminum, copper, stainless steel, and nickel, and can be produced in rolled or annealed tempers depending on application needs.

Key Features:-

-

Ultra-thin construction, typically below 0.2 mm in thickness.

-

Available in aluminum, copper, stainless steel, nickel, and other alloys.

-

Excellent flexibility, ductility, and resistance to corrosion and oxidation.

-

Used in packaging, electronic circuits, insulation, and aerospace shielding.

-

Can be supplied in rolls, sheets, or custom die-cut shapes as per application.

Applications of Sheets & Plates

-

Used extensively in construction for structural components and architectural cladding.

-

Critical in manufacturing pressure vessels, boilers, and heat exchangers due to high strength and heat resistance.

-

Widely employed in automotive and aerospace industries for body panels, chassis, and frames.

-

Used in shipbuilding and marine applications for corrosion-resistant hulls and structural parts.

-

Fabricated into industrial machinery parts, heavy equipment, and transportation components.

-

Essential in energy sectors including oil & gas pipelines, refineries, and power plants.